Our

History

We founded the company in 1996 with a simple mission.

To coin a common phrase, it’s been a journey!

We founded the company in 1996 with a simple mission – to create fine freestanding baths without the drawbacks of cast iron and acrylic.

This mission was dependent on developing a new material that resulted in a bath that was strong, durable and beautiful. Two years of creating numerous concoctions resulted in our unique Iso-Enamel material. A material that gives a faithful reproduction of the inside of original cast iron baths with a smooth, glass-like, white surface. It overcame cast iron’s extreme weight and high heat loss. An Albion bath is less than half the weight of a cast iron equivalent. When compared to acrylic, the surface is hard and durable.

As with most things in life, it didn’t end there. To do the job properly, the baths needed to replicate the shape and style of original tubs. With this in mind, we headed to the local reclamation yard to find an original cast iron bath. One that we felt had all the attributes of the traditional items.

On this day, we were in luck. A perfectly styled single-ended bath was spotted under a frayed tarpaulin. The exterior was rusty, the interior was scruffy, but the shape was perfect. From this original cast iron bath, the Albion story began.

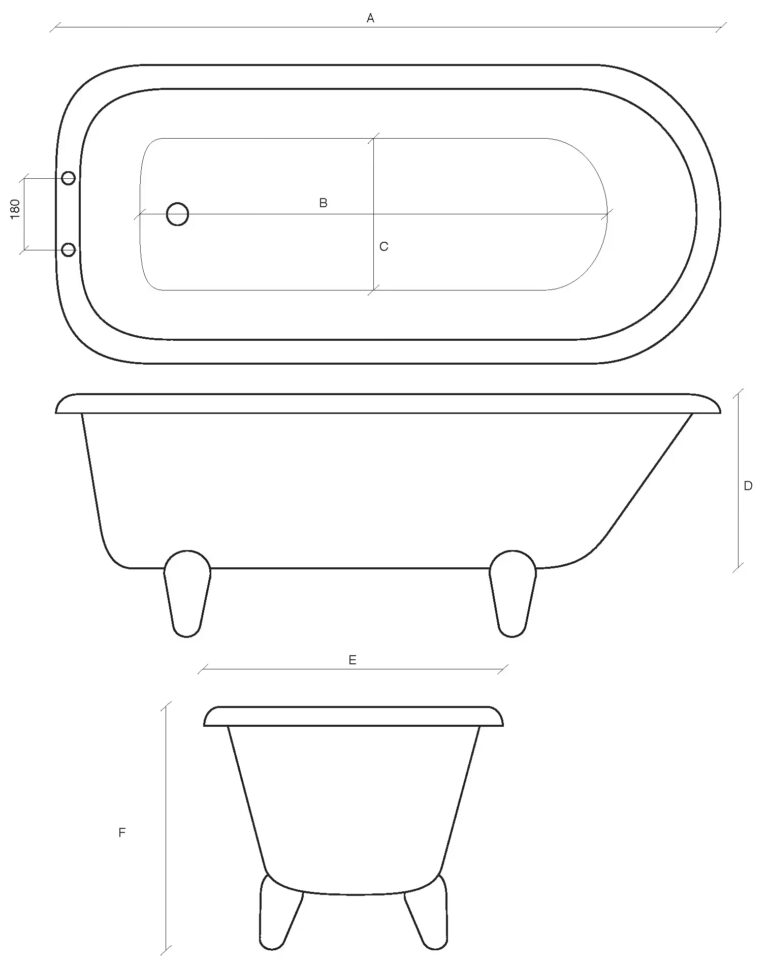

We took our Solus bath moulds directly from this shape and developed a unique moulding system for our new material. To keep this theme, we used the Solus as a basis for a number of other models.

Using this original bath had major benefits. The angles and curves were correct for the period. The feet affixed in the original way and, importantly, the size was a touch smaller than standard ‘built-in’ baths – meaning our new Solus could fit into spaces vacated by cheap acrylic tubs.

The more we worked, the more we realised how good our new material turned out to be. The white surface was durable, glossy, and resistant to modern cleaning products. The exterior was smooth and able to be finished in any choice of paint. Importantly, the material retained the heat in the bathing water. The difference to cast iron was drastic. Our customers reported that they could bathe for over an hour without topping-up with more hot water.

As the company grew, the range of baths increased with a range of sizes from 1200mm – 2000mm long. We were determined to offer our products for bathrooms both big and small.

To add practicality, we developed a number of wall-fitted models that combine bathing and showering. Our ever-popular Trident bath is a fine example of this concept.

We are constantly developing new products and expanding our manufacturing into new areas to complement our product lines.

Our journey is not over yet…

Notable Milestones

Our new bath material is developed and the Solus Bath is born from a cast iron original.

Geminus is born in the 1670mm length using an original cast iron bath as a pattern.

Imperium and Neptune arrive on the scene.

Our Torre baths enter the fold and the 1200mm version is made famous by Cameron Diaz in 'The Holiday' movie.

Our Torre Dee bath joins the line-up.

The Torre Corner bath enters production.

A new chapter begins as new owners take over the reigns at Albion Bath Co